Capabilities

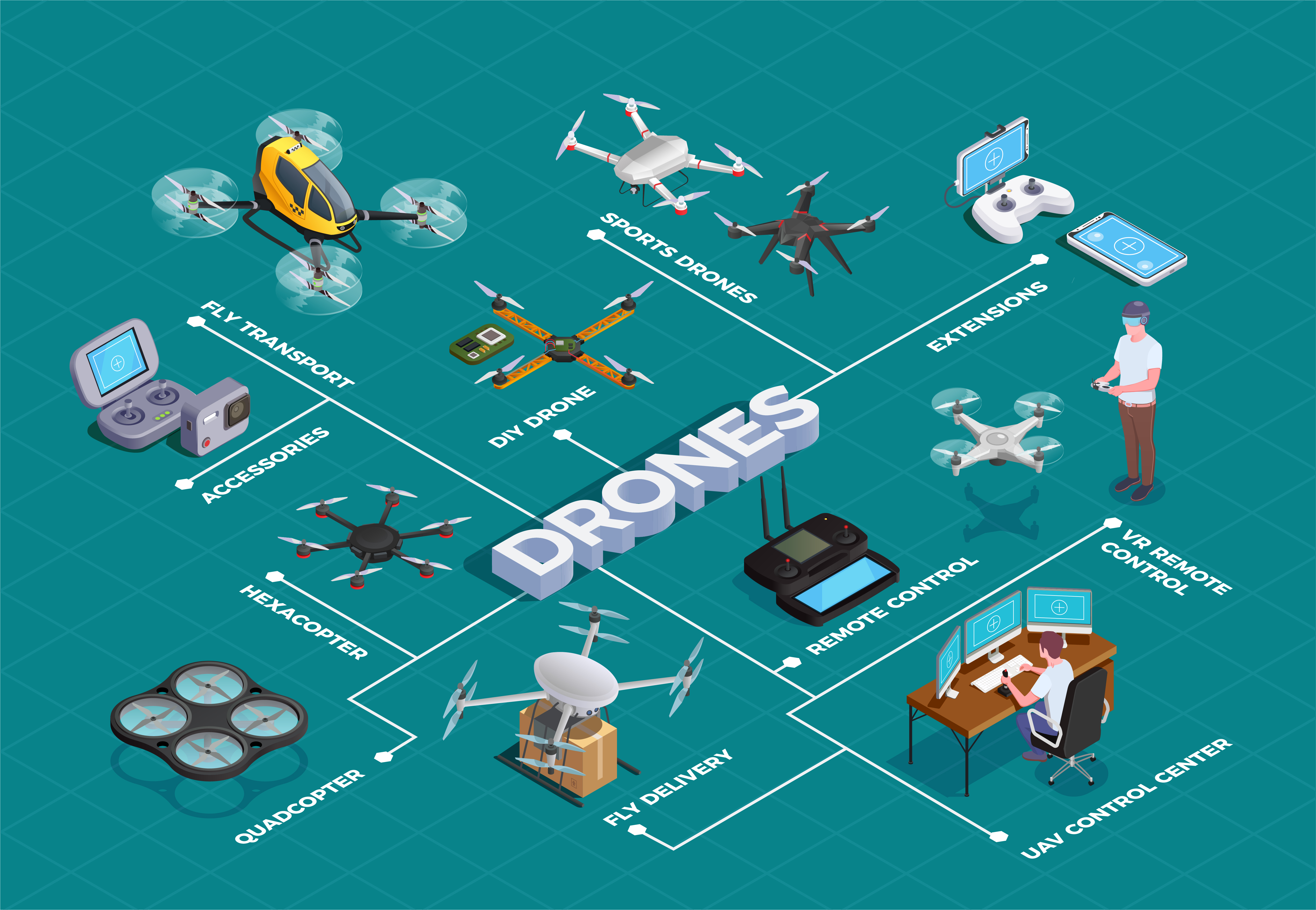

We specialize in end-to-end delivery of unmanned systems for fixed-wing and rotorcrafts (including helicopters). Our capabilities include:

- Airframe design and manufacturing with advanced composites

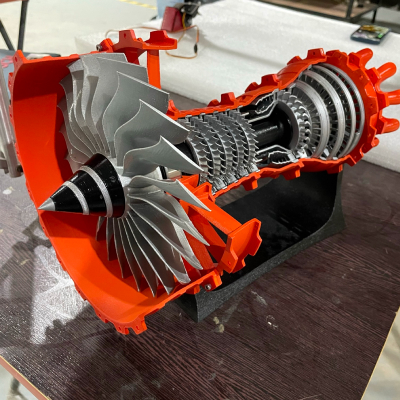

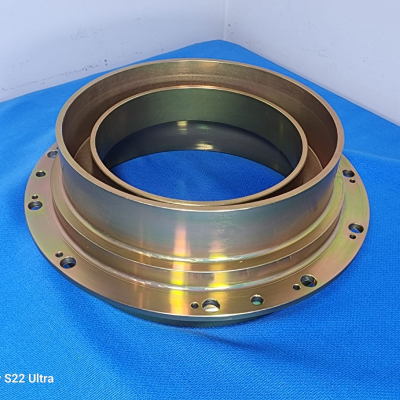

- Indigenization of imported platforms, including reverse engineering and spare parts production (e.g., Mi-17 engine components)

- Propulsion system selection and custom composite blade propellers

- Aircraft integration, testing, and avionics/payload integration

- Flight test planning and services, including UAV leasing, test pilots, and field services

- Consultation for unmanned system product development and industrialization.

Our Facility

Our 1200 sqft in-house facility is dedicated to prototyping, assembly, integration, and testing. We specialize in high-performance, lightweight composite parts using cost-effective methods such as wet layup, resin infusion, match die molding, and out-of-autoclave processes.

- 500 sqft Composite Layup Area

- Assembly & Bonding Area for assemblies up to 3m x 3m

- Hot Air Oven (2.5m x 2.5m x 1.5m) with PID controller for curing up to 180°C

- Vacuum System supporting 10 vacuum bags for continuous processing

- Trimming & Drilling Station with dust exhaust

- Paved Runway & Field for fixed-wing aircraft testing